“There are many processes & workforce employed at work. If I could automate the processes & create a simpler structure for employees to enhance productivity.”

About Sarman Leathers

Sarman Leathers is one of the leading exporters and manufacturers of leather and PU goods and accessories in India. From designing to developing to marketing and manufacturing premium quality leather goods and accessories, the company has a complete range for Men & Women. Situated in Delhi, Sarman Leathers is manufacturing products in the capital city for 20 years, and the firm is professionally managed by promoters in the leather industry.

The challenge

Being a company delivering products pan India, they needed a trained and efficient team so that their workflow doesn’t suffer.

The primary issue they were facing was:

Employee Retention:

They used to teach the process flow, guide the employee on how their business work, train them for months, and then the employees used to leave for better opportunities. This became a regular pattern in their company due to which their time, energy, and business was suffering majorly. They also suffered losses as their inventory processes were hampered. Sarman Leathers was searching for a permanent solution through which their company runs on an auto-pilot mode. They wanted a system that is not entirely dependent on employees instead works on its own.

Sarman Leathers contacted Zenscale seeking a solution to their long-standing problem. They expressed that they want to simplify their processes and create a framework understandable by an old and a new employee.

"We were searching for a permanent solution through which the company runs on an auto-pilot mode. We wanted a system that is not entirely dependent on employees instead works on its own."

New Castle Knitwears

Approach Followed

Recognizing their problem, we suggested a solution in parts to Sarman Leathers. We understood that they need a system that an old and new employee can learn & implement immediately. We suggested Flowcharts devised accurately as per their processes. The flowcharts suggested to Sarman Leathers resolved their Inventory issues and enhanced employee productivity.

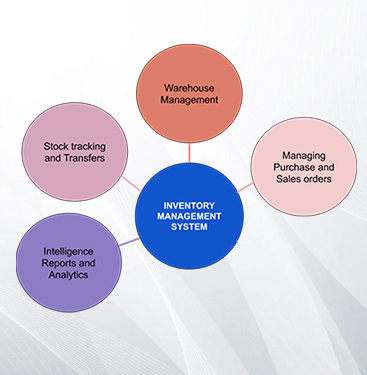

Zenscale customized the flowchart for Sarman Leather keeping their workload, staff, and processes in mind. This is a demonstration image explaining how inventory can be automated and managed in a single click.

Result

Impressed by the Flowcharts, Sarman Leathers instantly carried out the flows in their company. As the flow implementation began, their processes were improvised, and the system streamlined. They shared that with a steady and pre-defined system their training time reduced invariably and employee’s workload decreased. As the employees started to follow the flowcharts, Sarman Leathers experienced a massive increase in productivity and efficiency which further helped in growing & spreading their business worldwide. Satisfied with the implementation, their inventory troubles lessened and their company grew by 30% in a year.